Sufficient warranty and high value

8 years warranty for used vehicles or 600,000 km warranty for new vehicles

8 years warranty for used vehicles or 600,000 km warranty for new vehicles

Designed to absorb shocks on uneven roads

Maximum seven year plan with lowest interest rate of 1.98

Final interest rates rely on client’s evaluation scores

Principal and interest shall be paid back with an average amount

If you have any doubts on this plan

Contact deputy manager Shu-hui wang for more information

(Contact phone number:06-2530400 ext 11668,

fax: 06-2538885

mobile: 0926-108465)

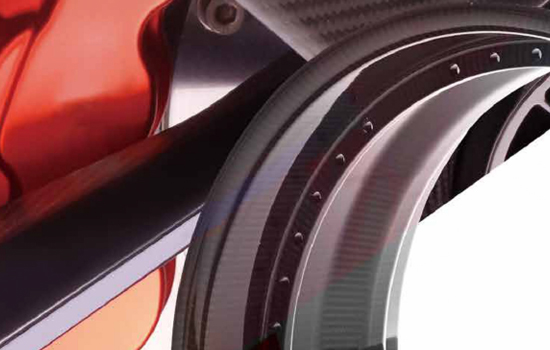

Carbon fiber is new fiber material made up of over 95% carbon and yields high strength and rigidity. It is lighter than aluminum and harder than steel; carbon fiber is also corrosion resistance and unmalleable. Bonny provides two-piece carbon fiber wheel with the rim solely made from carbon fiber.

Carbon fiber wheels has remarkable dampening effect, highly maneuverable feature and extreme passenger convenience. The unsprung mass is reduced due to the lightweight carbon composite wheels replacement. Suspension response time is massively shortened. Acceleration is easily operated with faster rate. Braking is improved with better performance.

Carbon fiber wheels has remarkable dampening effect, high maneuverability and precise steering and comformtable ride experience. With lighweight carbon fiber wheels, the unsprung mass is reduced. It makes suspension response time noticeably shortened, acceleration faster and better braking performance.

According to the automobile research data, by reducing 1 kg of unsprung mass is equivalent to reducing 10kg of the sprung mass. For every 10% reduction of the vehicle weight, there will be 6-8% less fuel consumption along with 5-6% less in emission.

For compatible models, please contact:

Northern Taiwan Customer Service Line:

Central and southern Taiwan Customer Service Line:

7-year financing plan

German Technical Inspection Association

German STVZO standard: NOV 1998 guidelines for testing and inspections on wheels attached to cars and trailers.

Inspector: CAAM Wheel inspection center Co, Ltd.

Society of Automotive Engineers, short for SAE, of which standard has authority over major auto industry and others with certain parts being used as American national standards.

Aftermarket Wheels - Passenger Cars and Light Truck - Performance Requirements and Test Procedures

Inspector: Smither Rapra (Suzhou) Testing Co, Ltd.

Four-month test durations with 10,000 km driving distance. The test conductors were satisfied; the rides were comfortable according to the testers. Inspections were focused on static stiffness ,brittleness , dynamic deformation of the rims before and after driving tests.

The result conformed to the standards

Sichuan-Tibet road test

16 months of preparations, tested for 180 hours in 15 days; the test was carried out by a team of 8 professional.

The road tests mainly conducted on bumpy, muddy, shoal curbstones, steppes or gravel roads. Highest altitude reached was 5,100 elevation above the sea level.

Inspections were focused on static stiffness, brittleness, dynamic deformation and appearance of the rims. It is qualified as per standards as a result.